RIKON VENEER

Rikon Veneer

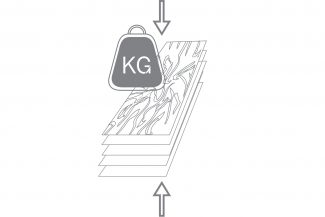

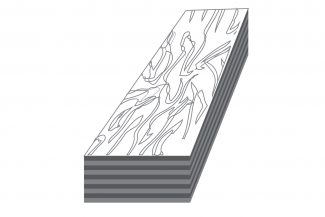

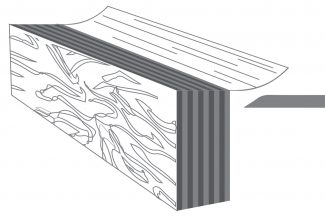

Reconstituted veneer is man-made veneer produced from fast growing wood species, laid and sometimes dyed to mimic the look of their real wood counterparts. Wood species used in making of reconstituted veneer have an average of 6-10 years of life before being ready for harvesting versus 80-150 years for most hardwoods of which natural veneer is taken. Some of the advantages of reconstituted veneers are:

Grain and color consistency from sheet to sheet.

Defect-free veneers.

Sustainable.

Ideal sizes that reduce wastage.

Wide color and grain spectrum.

Endless design possibilities.

Visit rikonveneer.com for more information.

Why Rikon

Backed with strong knowledge and long history in natural veneer and lumber industry and having witnessed and believed in the evolution of recon veneer, Rikon was established with the goal of offering its partners the latest in veneer trends and the highest quality in the industry with superior service and affordable prices.

*For more information please visit wwww.rikonveneer.com